Four Key Points to Note in CNC Lathe Machining

2022-03-10

CNC lathe machining is a high-precision, high-efficiency mechanical processing method that uses digital information to control the displacement of parts and tools on automated machine tools. Since CNC lathe machining completes all turning processes in one setup with continuous automatic processing, the following points should be noted during CNC lathe machining. 1. Pay attention to the selection of cutting parameters The three key elements of cutting conditions in CNC lathe machining are cutting speed, feed rate, and depth of cut, which can directly cause tool damage. As the cutting speed increases, the temperature at the tool tip rises, leading to mechanical, chemical, and physical wear. A 20% increase in cutting speed can reduce tool life by half. The impact of feed rate on tool wear is less than that of cutting speed, but a larger feed rate increases cutting temperature, resulting in greater tool wear. Although the depth of cut has less impact on the tool compared to cutting speed and feed rate, when cutting with a small depth of cut, the material being cut can produce a hardened layer, which can also affect tool life. 2. Pay attention to the selection of tools 1) For rough turning, choose tools with high strength and durability to meet the requirements of large back cutting amounts and high feed rates. 2) For finishing, select tools with high precision and durability to ensure the required machining accuracy. 3) To reduce tool change time and facilitate tool setting, try to use machine-clamped tools and machine-clamped inserts. 3. Pay attention to the selection of fixtures 1) Preferably use universal fixtures to clamp workpieces, avoiding the use of special fixtures; 2) Ensure that the positioning reference of the parts coincides to reduce positioning errors. 4. Pay attention to the selection of machining paths The machining path refers to the trajectory and direction of the tool relative to the part during the CNC lathe machining process. 1) It should ensure the required machining accuracy and surface roughness; 2) The machining path should be as short as possible to reduce the tool's idle travel time.

See more.Basic Knowledge Required for Gear Design

2022-02-10

In mechanical design, the design of gears as mechanical elements requires essential technical knowledge. This is true even if you choose to use pre-designed gears. The knowledge of gears that needs to be mastered includes various calculation formulas used for gear strength and size calculations, types of gears, specialized terminology related to gears, gear pair speed ratios and directions of rotation, tooth profiles and tooth thickness, backlash, ISO and AGMA standards related to precision levels, assembly accuracy of gears, gear materials and heat treatment, hardness of gears, lubrication issues when using gears, strategies for noise and damage problems, geometric tolerances used in gear drawing, and special geometric symbols used in mechanical drafting.

See more.Analysis of Errors Affecting the Contact Accuracy in Gear Processing

2022-01-04

The contact conditions of the gear tooth surfaces usually have a direct impact on the uniformity of load distribution in gear transmission. During rolling teeth, the main reasons affecting the contact accuracy in the tooth height direction are the tooth shape tolerance △ff and the base surface limit deviation △fpb. The main reason affecting the contact accuracy in the tooth width direction is the tooth direction tolerance △Fβ. The main causes of tooth direction tolerance are: 1. There is a parallelism error between the guide rail of the gear hobbing machine's tool holder and the rotation axis of the worktable. 2. The assembly deviation of the gear blank caused by the runout of the spindle and the non-parallelism of the bottom surface of the gear blank and the two end surfaces of the washer can lead to gear positioning errors. 3. When rolling helical gears, in addition to the aforementioned influencing factors, the calculation error of the machine tool's differential gears can also have a certain impact on the tooth difference of the gear.

See more.Gears have a wide range of applications.

2021-12-20

The market application range of Shenyang gears is quite broad, but not every application area can utilize the core products of sprocket manufacturers. Only those fields that truly possess universal characteristics and have a large volume of sprocket applications hold practical investigation and research value. Currently, the core products suitable for application from sprocket manufacturers include: first, applications in transmission systems, commonly found in mechanized transportation tools and machinery. The main function in this field is to drive and relate to other aspects concerning speed, such as industrial gearboxes and vehicle wheel drive systems. Almost all systems that use sprocket products also require various types of gear products, and multiple mechanical devices and components must be optimized and matched to achieve the best sprocket application effect. If a sprocket experiences severe wear during use, it must be replaced or refurbished promptly. It is essential to use a certain amount of lubricating oil during daily operations to reduce wear. Additionally, sprocket manufacturers inform us that new sprockets should not be used together with old sprockets, as this can create a certain impact force and easily lead to breakage. Sprockets are transmission components and consumables that need to be replaced regularly to ensure the normal operation of equipment. When a sprocket needs to be replaced, the old sprocket must be removed and a new one installed, which requires professional personnel to operate. Sprocket manufacturers also provide corresponding installation and usage recommendations for different products to assist users during sprocket installation. Sprocket manufacturers process and produce different models and specifications of finished sprockets for various devices, with similar structural performance and installation methods. When purchasing sprockets, it is important to choose sprockets that match the equipment to ensure smooth installation and normal use.

See more.Introduction to Spiral Bevel Gears

2021-11-12

The tooth profile of spiral bevel gears is arc-shaped, and they are generally conical in shape, resembling an umbrella, hence the name spiral bevel gear. Spiral bevel gears are transmission components that can provide stable transmission ratios with smooth and low-noise operation. They are known by different names in various regions, including spiral bevel gears, arc tooth bevel gears, arc tooth conical gears, circular arc conical gears, and spiral conical gears. Spiral bevel gears have high transmission efficiency, stable transmission ratios, large arc overlap coefficients, high load capacity, smooth and reliable operation, compact structure, energy-saving and material-saving features, space-saving, wear resistance, long service life, and low noise. Among various mechanical transmissions, spiral bevel gears have the highest transmission efficiency, providing significant economic benefits for various transmissions, especially high-power transmissions. They require the least space for the same torque compared to belt and chain transmissions. The transmission ratio of spiral bevel gears is permanently stable, which is often a basic requirement for the transmission performance of various mechanical devices. Spiral bevel gears are reliable in operation and have a long lifespan. The size specifications of spiral bevel gears range from a diameter of 10mm to 1600mm, with a modulus of 1 to 36. The precision levels of spiral bevel gears range from GB5 to GB8. Depending on the design methods, processing methods, and processing equipment, spiral bevel gears can be classified into German Klingelnberg spiral bevel gears, American Gleason spiral bevel gears, and Swiss Oerlikon spiral bevel gears, commonly referred to as Klingelnberg spiral bevel gears, Gleason spiral bevel gears, and Oerlikon spiral bevel gears. There are some minor differences between these different types of spiral bevel gears, but many of the main parameters are quite similar. According to the different application environments of spiral bevel gears, various parameters can vary significantly. Based on the usage environment, spiral bevel gears can be further divided into centrifugal classifier series spiral bevel gears, vertical coal mill spiral bevel gears, textile machinery series spiral bevel gears, reducer series spiral bevel gears, automotive transmission series spiral bevel gears, rolling mill machinery series spiral bevel gears, mining machinery series spiral bevel gears, wheeled loader series spiral bevel gears, lateral mixer series spiral bevel gears, DCY reducer spiral bevel gears, DBY reducer spiral bevel gears, universal milling head spiral bevel gears, wire drawing machine series spiral bevel gears, cement vertical mill spiral bevel gears, oilfield drilling rig series spiral bevel gears, construction machinery series spiral bevel gears, high-frequency welded pipe spiral bevel gears, stainless steel welded pipe spiral bevel gears, pipe-making machinery spiral bevel gears, cold bending forming machine series spiral bevel gears, hard tooth surface spiral bevel gears, and other series of spiral bevel gears. Spiral bevel gears are widely used in domestic and international oilfield petrochemical machinery, various machine tools, various machining equipment, construction machinery, metallurgical equipment, rolling mill machinery, mining machinery, coal mining machinery, textile machinery, marine machinery, shipbuilding industry, aerospace, forklifts, elevators, reducers, aircraft manufacturing, and many other industrial fields. When used in various mechanical devices, spiral bevel gears demonstrate their excellent performance and are favored by customers from aerospace equipment manufacturing plants, shipbuilding yards, construction machinery factories, metallurgical equipment factories, rolling mill spare parts factories, rolling mill machinery factories, rolling mills, metallurgical machinery factories, mining machinery factories, coal mining machinery factories, oilfield petrochemical machinery factories, textile machinery factories, machine tool factories, equipment companies, elevator companies, aircraft manufacturing plants, reducer factories, coal mining machinery factories, light industry machinery factories, rolling mills, rolling equipment factories, metallurgical equipment factories, and other various customers.

See more.2021-07-23

The demand for corresponding automotive gear processing machine tools and large-scale gear processing machine tools is rapidly increasing. Domestic gear processing machine tools have ushered in an opportunity for high-level development. With the continuous increase in demand for gear processing machine tools, the number of domestic enterprises involved in the manufacturing of gear processing machine tools is also on the rise. It is well known that gears are the most fundamental mechanical transmission components, with a large demand and wide application. Gear machine tools are recognized as one of the products with the highest technical content, the most components, and the most complex structures in the machine tool industry. However, the gear machine tool industry in China has always been in an awkward position. Gear processing machine tools have a very wide range of applications. Nowadays, some enterprises have already responded to the market, actively adjusting their industrial structure, continuously expanding product application fields, and providing new machine tools with high speed, high stability, and high precision to popular industries to meet industry needs. In the future, the demand for gear processing machine tools across various industries will be very strong, and enterprises can only seize these opportunities to achieve higher-level development. The production and manufacturing model has not changed. Compared to this model, many foreign gear machine enterprises have gained unique market shares by relying on advantages in technology, management, and capital, gradually entering the market. Faced with the strong market encroachment of foreign products, the industry is facing a serious market crisis, which has greatly stimulated domestic enterprises, prompting them to form a competitive model of resistance. They have gradually increased their investment in technology and management, striving to compete with foreign products and protect the domestic market. With the rapid development of the domestic economy in recent years and the increase in exports of the heavy machinery industry, the development of this important foundational industry has been exceptionally rapid. Gear reducer enterprises are expanding their production and sales scale, continuously improving processing capabilities and technical levels. The future market prospects for the gear reducer industry will be very promising.

See more.2021-06-10

A worm gear refers to a gear that has one or more helical teeth and meshes with a worm wheel to form a crossed-axis gear pair. Its pitch surface can be cylindrical, conical, or annular, and there are four categories: Archimedean worm, involute worm, normal straight profile worm, and conical enveloping cylindrical worm. Transmission Structure Worm drive consists of a worm and a worm wheel, used to transmit motion and power between crossed axes, typically with a crossing angle of 90°. In general worm drives, the worm is the driving component. In appearance, the worm resembles a bolt, while the worm wheel looks like a helical cylindrical gear. During operation, the teeth of the worm wheel slide and roll along the helical surface of the worm. To improve the contact condition of the teeth, the worm wheel is made into an arc shape along the tooth width direction, allowing it to partially envelop the worm. This way, the engagement between the worm and worm wheel is line contact rather than point contact.

See more.Advantages and Disadvantages of Turbines

2021-05-18

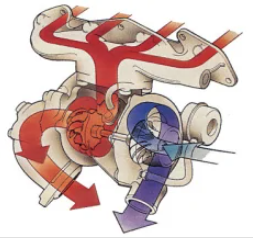

Under the condition of not changing the engine displacement, turbocharged engines can significantly increase the engine's power and torque. Generally speaking, the power and torque of an engine with a turbocharger can increase by 20% to 30%. On the other hand, turbocharging can improve the fuel economy of the vehicle. However, turbocharging also has its drawbacks, one of which is turbo lag. This is because the turbo needs to wait for the engine to reach a certain RPM (around 2000 RPM) before it can start working. Additionally, turbocharging can lead to increased noise and exhaust heat issues. Furthermore, the components within a turbocharged engine often operate in high-temperature and high-stress environments, which means that such engines have special requirements for engine oil. The oil must have good wear resistance, high-temperature durability, quick establishment of a lubricating oil film, high oil film strength, good stability, and low viscosity.

See more.What impact does heat treatment have on bevel gears?

2021-04-14

The proper processing of bevel gears is very important, and heat treatment is a crucial step in the processing of bevel gears. So, what impact does heat treatment have on bevel gears? Heat treatment alters physical properties, such as surface hardness, which helps prevent wear on the teeth and bearing surfaces. It also changes the fatigue life of the gears by generating residual compressive stresses, which help prevent pitting and deformation caused by high contact stresses on the gear teeth. These same compressive stresses can prevent fatigue failure at the root of the gear due to periodic bending. Heat treatment is a key and complex factor in gear manufacturing, affecting the performance of each gear in transmitting power or transferring motion to other components. Heat treatment optimizes performance and extends the lifespan of gears in use by altering their chemical, metallurgical, and physical properties. These properties are determined by considering the gear's geometry, power transmission requirements, stress at different points within the gear under load, load cycle rates, material types, design of mating components, and other operating conditions. Therefore, heat treatment of bevel gears can lead to good performance, meeting production demands.

See more.2021-03-12

Arc gears: Gears with an arc-shaped tooth profile that engage at points. Arc gear transmission typically has two engagement forms: the pinion has a convex arc tooth profile, while the gear has a concave arc tooth profile, known as single arc gear transmission. In the research of modern gear reduction motors, arc gears are set to replace cylindrical gears as the focus of development. In terms of stability, torque, and service life, arc gears have significant advantages over cylindrical gears, and their development trend is also promising. In China, single arc gear transmission has been used in high-speed heavy-load equipment such as steam turbines, compressors, and low-speed heavy-load rolling mills; double arc gear transmission has been used in the main drive of large rolling mills.

See more.