Contact analysis of spiral bevel gear transmission with errors

2021-02-09

Based on the theory of multi-body system error modeling and the principle of gear meshing, a method for error tooth contact analysis (ETCA) of spiral bevel gears is proposed, which includes geometric errors of machine tool motion and installation errors of gear pairs. Taking the arc tooth spiral bevel gear processed by the SGM method (large wheel generating method and small wheel deformation method) as an example, the ETCA analysis is conducted to obtain the quantitative relationship between machine tool motion errors, installation errors, and the machining quality of spiral bevel gear tooth surfaces. A comparative analysis of the results of ETCA and TCA shows that machine tool motion errors and installation errors have a significant impact on the tooth surface contact quality of spiral bevel gears. To achieve more accurate reverse adjustment of machining parameters through tooth surface contact analysis, the analysis results of ETCA are used to guide the reverse adjustment of machining parameters more reasonably.

See more.Applications of Spiral Bevel Gears

2021-01-08

Spiral bevel gears are widely used in domestic and international oilfield petrochemical machinery, various types of machine tools, various machining equipment, construction machinery, metallurgical equipment, steel rolling machinery, mining machinery, coal mining machinery, textile machinery, ship machinery, shipbuilding industry, aerospace, forklifts, elevators, reducers, aircraft manufacturing, and many other industries. When used in various mechanical equipment, spiral bevel gears demonstrate their excellent performance and are favored by a wide range of customers, including aerospace equipment manufacturers, shipbuilding factories, construction machinery manufacturers, metallurgical equipment manufacturers, steel rolling parts manufacturers, steel rolling machinery manufacturers, steel mills, metallurgical machinery manufacturers, mining machinery manufacturers, coal mining machinery manufacturers, oilfield petrochemical machinery manufacturers, textile machinery manufacturers, machine tool manufacturers, equipment companies, elevator companies, aircraft manufacturers, reducer manufacturers, coal mining machinery manufacturers, light industry machinery manufacturers, steel mills, steel rolling equipment manufacturers, and metallurgical equipment manufacturers.

See more.2020-12-06

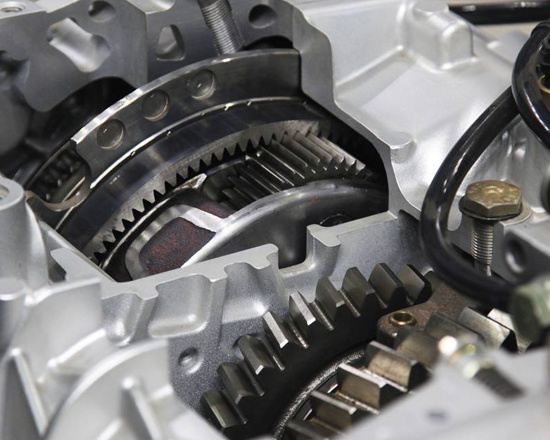

Gears play an important role in the machinery industry. However, with increased usage over time, inadequate daily maintenance of gears will inevitably affect their performance and even shorten their lifespan. So how should gears be maintained? Here are some tips from a helical gear processing manufacturer. 1. Regular Maintenance. Depending on the field of use, frequency of use, and wear conditions, gears should be maintained regularly. Before maintenance, check the quality of the maintenance oil; if it does not meet the usage requirements, it should be replaced promptly. Especially for precision gears, the specified oil should be used. If the technical indicators of the oil do not meet the usage requirements, the maintenance effect will not be achieved, thus affecting normal use. 2. Timely Replacement of Worn Parts. If gears are used relatively frequently, wear will inevitably occur. At this point, maintenance should be strengthened; otherwise, wear will worsen, leading to gear damage. Additionally, when disassembling and installing, specialized tools should be used. Follow the steps for disassembly and installation to avoid reckless actions that could damage the gears. The above are some key points regarding gear maintenance. For more information about gears and helical gears, please continue to follow the Great Wall Gear Factory website!

See more.Introduction to the Characteristics of Arc Tooth Synchronous Belt Wheel Transmission

2020-10-15

The technical characteristics of the arc tooth synchronous belt wheel drive have been summarized, highlighting the differences between arc tooth synchronous belt wheels and trapezoidal tooth synchronous belt wheels as well as T-type synchronous belt wheels with square teeth. The arc tooth design allows for the transmission of high power, with the power capacity of the transmission system being 3-5 times greater than that of trapezoidal and T-type teeth. It mainly uses soft or medium-hard tooth surfaces, and when using hard tooth surfaces, low-profile teeth are generally preferred. The arc gear transmission is suitable for helical gears but not for spur gears. The relative curvature radius is greater than that of involute gears, resulting in a higher contact strength. When the sensitivity to center distance changes is greater than that of involute gears, the requirements for cutting tooth length are high, and radial variable position cutting is not allowed, allowing for strict control of assembly errors. Arc gears can be classified into single arc gears and double arc gears. Under the same conditions, the contact line strength of single arc gears is higher than that of involute gears, while their bending strength is lower than that of involute gears.

See more.2020-09-11

Spiral bevel gears are widely used in domestic and international oilfield petrochemical machinery, various types of machine tools, various machining equipment, construction machinery, metallurgical equipment, steel rolling machinery, mining machinery, coal mining machinery, textile machinery, ship machinery, shipbuilding industry, aerospace, forklifts, elevators, reducers, aircraft manufacturing, and many other industries. When used in various mechanical equipment, spiral bevel gears demonstrate their excellent performance and are favored by a wide range of customers, including aerospace equipment manufacturers, shipbuilding factories, construction machinery manufacturers, metallurgical equipment manufacturers, steel rolling parts manufacturers, steel rolling machinery manufacturers, steel mills, metallurgical machinery manufacturers, mining machinery manufacturers, coal mining machinery manufacturers, oilfield petrochemical machinery manufacturers, textile machinery manufacturers, machine tool manufacturers, equipment companies, elevator companies, aircraft manufacturers, reducer manufacturers, coal mining machinery manufacturers, light industry machinery manufacturers, steel mills, steel rolling equipment manufacturers, and metallurgical equipment manufacturers.

See more.What are the processes for gear machining in Shenyang?

2020-08-08

1. Casting and forging still remain widely used blank casting processes for automotive gear components. In recent years, wedge rolling technology has been extensively promoted in the processing of shaft components. This technology is particularly suitable for producing complex stepped shafts, as it not only offers high precision and small machining allowances but also has high production efficiency. 2. Normalizing The purpose of this process is to achieve a hardness suitable for subsequent gear cutting processing and to prepare the structure for final heat treatment, effectively reducing thermal deformation during heat treatment. The gear steel material used is generally 20CrMnTi. Normalizing is significantly affected by personnel, equipment, and environmental factors, making it difficult to control the cooling rate and uniformity of the workpiece, resulting in large hardness variations and uneven metallographic structures, which directly affect metal cutting processing and final heat treatment, leading to significant and irregular thermal deformation, making it difficult to control the quality of the parts. Therefore, isothermal normalizing technology is adopted. Practical experience has shown that isothermal normalizing effectively addresses the shortcomings of conventional normalizing, resulting in stable and reliable product quality. The basic requirement for cage design is to meet the maximum load capacity and rotational precision and speed of the bearing within a certain space and structural strength. The guiding method for the inner and outer diameters or rolling elements can be determined based on the operating conditions of the bearing in the main machine and the requirements for guiding clearance, thus confirming the structure and main parameters. When rolling bearings operate, heat and wear are generated due to sliding friction, especially under high-speed conditions. The effects of centrifugal force and inertial force accelerate the collision and friction wear and heating of the rolling elements, inner and outer rings, and cage. In severe cases, this can lead to cage burning and cracking, causing the bearing to fail to operate normally. Cage damage accounts for a significant proportion of bearing failure modes, and the quality of the cage material is one of the main reasons for cage damage. Therefore, the material for bearing cages is required to have excellent mechanical strength, dimensional stability, and outstanding plasticity and machinability, among other functions. The content of this article is sourced from the internet. If there are any issues, please contact us!

See more.2020-04-18

Gears are toothed mechanical components that can mesh with each other, and their application in mechanical transmission and the entire mechanical field is extremely widespread. Modern gear technology has reached: gear module from 0.004 to 100 millimeters; gear diameter from 1 millimeter to 150 meters; power transmission can reach over 100,000 kilowatts; rotational speed can reach hundreds of thousands of revolutions per minute; and the highest circumferential speed can reach 300 meters per second. With the development of production, the smooth operation of gears has received attention. In 1674, Danish astronomer Romer first proposed using an epicycloid as the tooth profile curve to achieve smooth-running gears.

See more.2020-04-10

Bevel gears, also known as conical gears, are used for transmission between intersecting shafts. Compared to cylindrical gears, they can change the direction of transmission. The single-stage transmission ratio can reach up to 6, with a maximum of 8. 1. Straight and helical bevel gears are relatively simple to design, manufacture, and install, but they produce more noise and are used for low-speed transmission (<5 m/s); straight bevel gears can transmit power up to 370 kilowatts at a circumferential speed of 5 meters per second. Helical bevel gears operate smoothly and have a higher load capacity, but they are more difficult to manufacture and are less commonly used. 2. Curved bevel gears feature smooth transmission, low noise, and high load capacity, making them suitable for high-speed heavy-load applications.

See more.What are the development trends of mining machinery?

2020-04-03

1. The status of mining machinery is foundational: Developed countries place great importance on the development of the mining machinery manufacturing industry. Not only does it account for a significant share in their national industries, but it also leads in accumulation, employment, and contribution. Moreover, the equipment manufacturing industry provides an important material foundation for the development and production of new technologies and products, making it an indispensable strategic industry for a modern economy. Even industrialized countries that have entered the "information society" highly value the development of the machinery manufacturing industry. 2. Intensification of multinational mergers and acquisitions in the mining machinery manufacturing industry: Modern mergers and acquisitions in mining machinery no longer solely emphasize competition. Instead, forming strong alliances to establish mining machinery enterprises has become a primary means of gaining competitive advantages.

See more.The Development of Shenyang Great Wall Gear Factory

2020-03-28

The office address of Shenyang Great Wall Gear Factory is located in the northeastern metropolis known as the "birthplace of the dynasty, home to two emperors" - Shenyang. The address is 362 Tianshan Road, Huanggu District, Shenyang. The factory was registered on August 1, 1988, with the Shenyang Huanggu District Market Supervision Administration. Over the past 32 years of development, we have always provided our customers with quality products, technical support, and comprehensive after-sales service. Our factory mainly engages in gear processing. We have excellent products and a professional sales and technical team. Our factory belongs to the Shenyang gear industry. If you are interested in our products and services, we look forward to your online message or visit.

See more.